- Products

- Fans

- By Mounting Type

- Fan Selector

- Fan Controllers

- Controllers

- Run-on timer

- Ancillaries

- Prefab Modular Assemblies

- Mounting Feet

- Matching Flanges

- Ducting

- Attenuators

- Acoustic Louvres

- Cross Talk Attenuators

- VAV Diffusers

- Electronic Diffusers

- Thermo-disk Diffusers

- Healthy indoor environment

- Technical Library

- Adjustable Pitch

- Axial Flow Fans

- Motors

- Types and Specifications

- Noise & Acoustic

- Installation

- Inst. & Maint. Instructions

- Do's and Don'ts

- Downloads

- Tech Talk

- Latest Issues

- Brochures

- Catalogue

- Catalogue Download

- Selection Program

- Revit Models

- Revit Models Download

- Contact Us

- Contact Addresses

- New Zealand

- Europe

- Requests/enquiries

- Requests/enquiries

- Key Projects

- Projects

- Domestic

- Fire Safety & Hazardous

- Industrial

- Sports & Leisure

- About Us

- About Fantech

- About Fantech

- History of Innovation

- Privacy Policy

- Privacy Policy

- Terms of Use

- Terms of Trading & Quotation

- Terms of Trading & Quotation

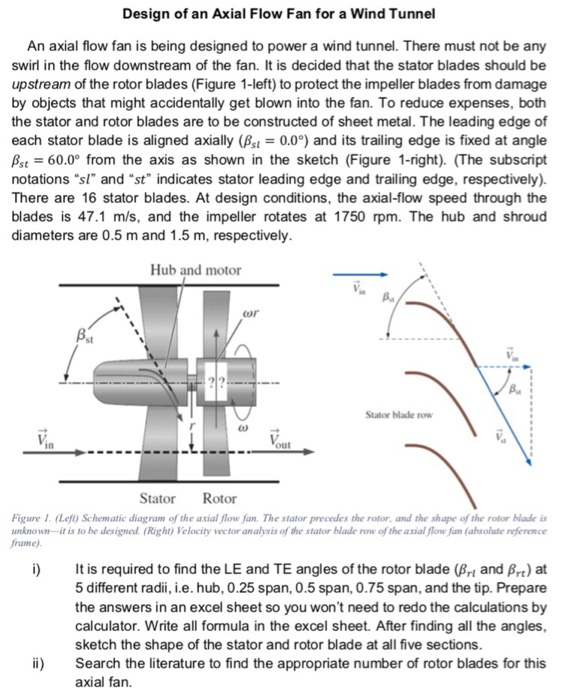

- The operating environment of a typical engine-cooling fan has favored axial-flow fans, and, at the same time, posed obstacles to successful adoption of alternative fan types. All applications of fans in ventilating, cooling, heating, and air conditioning processes have their unique set of environmental factors that dictate the fan design, but.

- A companion tool to Glenn Research Center's ACD software (LEW-17448), ACOD is streamline analysis code for predicting the off-design performance of multistage axial-flow compressors. Flow, blading, and loss are modeled similarly to ACD.

- As long as the cross-sectional area of a fan's diffuser (outer casing; Ac) is greater than the surface area of the outside diameter of the impeller (A or A o for axial and centrifugal respectively), the fan will exhaust 100% of volumetric flow with the same pressure variation as generated by the impeller (δp). As the diffuser area is reduced.

In axial fans air is discharge parallel to fan axis.

Suitable for low static pressure applications where high flow rate is required

Motor generally inside air stream, direct drive.

Advantages of axial fans are: Low cost and high air volume.

Disadvantages of axial fans are: higher noise, less efficiency and Low static pressure.

Types of axial fans are: Tube Axial, Vane Axial and Propeller.

1- Vane Axial

The highest axial fan efficiency.78-85%

Medium static pressure applications up to 8 inches (2.0 KPa).

Generally have guide vanes inside the fan housing to reduce air turbulence.

Airfoil blades can be fixed, controllable or adjustable pitch.

Large hub diameter usually greater than half fan tip diameter.

Cylindrical tube housing, close to fan tip diameter.

Guide vanes are used to control airflow and fan static pressure. Guide vanes can be upstream or downstream from impeller.

By using controllers, vane axial fans were widely used to control air flow. High noise levels and high initial cost of vane axial fans with variable vane guides make it uneconomical comparing to variable speed motors.

ications like exhaust systems in fume exhaust, and some industrial applications.

2- Tube Axial

Peak Efficiency up to 67-72%

Suitable for low static applications up to 1″(250Pa).

Four to eight blades.

Medium hub diameter close to half fan tip diameter. (Hub-to-Tip Ratio)

Cylindrical tube housing, close to fan tip diameter.

Performance curve dips to left of peak pressure. Fan Operating in this region shall be avoided.

Circular pattern air discharge.

Fan blades can be fixed thickness cross section or airfoil blades.

Circular pattern air discharge.

Applications: Fan is suitable for ductless or short duct applications.

Tube axial fan Red hat enterprise linux 7 iso free download 32 bit.

Axial Flow Turbine Engine Design

- The operating environment of a typical engine-cooling fan has favored axial-flow fans, and, at the same time, posed obstacles to successful adoption of alternative fan types. All applications of fans in ventilating, cooling, heating, and air conditioning processes have their unique set of environmental factors that dictate the fan design, but.

- A companion tool to Glenn Research Center's ACD software (LEW-17448), ACOD is streamline analysis code for predicting the off-design performance of multistage axial-flow compressors. Flow, blading, and loss are modeled similarly to ACD.

- As long as the cross-sectional area of a fan's diffuser (outer casing; Ac) is greater than the surface area of the outside diameter of the impeller (A or A o for axial and centrifugal respectively), the fan will exhaust 100% of volumetric flow with the same pressure variation as generated by the impeller (δp). As the diffuser area is reduced.

In axial fans air is discharge parallel to fan axis.

Suitable for low static pressure applications where high flow rate is required

Motor generally inside air stream, direct drive.

Advantages of axial fans are: Low cost and high air volume.

Disadvantages of axial fans are: higher noise, less efficiency and Low static pressure.

Types of axial fans are: Tube Axial, Vane Axial and Propeller.

1- Vane Axial

The highest axial fan efficiency.78-85%

Medium static pressure applications up to 8 inches (2.0 KPa).

Generally have guide vanes inside the fan housing to reduce air turbulence.

Airfoil blades can be fixed, controllable or adjustable pitch.

Large hub diameter usually greater than half fan tip diameter.

Cylindrical tube housing, close to fan tip diameter.

Guide vanes are used to control airflow and fan static pressure. Guide vanes can be upstream or downstream from impeller.

By using controllers, vane axial fans were widely used to control air flow. High noise levels and high initial cost of vane axial fans with variable vane guides make it uneconomical comparing to variable speed motors.

ications like exhaust systems in fume exhaust, and some industrial applications.

2- Tube Axial

Peak Efficiency up to 67-72%

Suitable for low static applications up to 1″(250Pa).

Four to eight blades.

Medium hub diameter close to half fan tip diameter. (Hub-to-Tip Ratio)

Cylindrical tube housing, close to fan tip diameter.

Performance curve dips to left of peak pressure. Fan Operating in this region shall be avoided.

Circular pattern air discharge.

Fan blades can be fixed thickness cross section or airfoil blades.

Circular pattern air discharge.

Applications: Fan is suitable for ductless or short duct applications.

Tube axial fan Red hat enterprise linux 7 iso free download 32 bit.

Axial Flow Turbine Engine Design

Axial Fan Blade Design

Sunken temple statue order. 3- Propeller Axial:

Peak Efficiency up to 67-72% Apa fungsi ikon clip art.

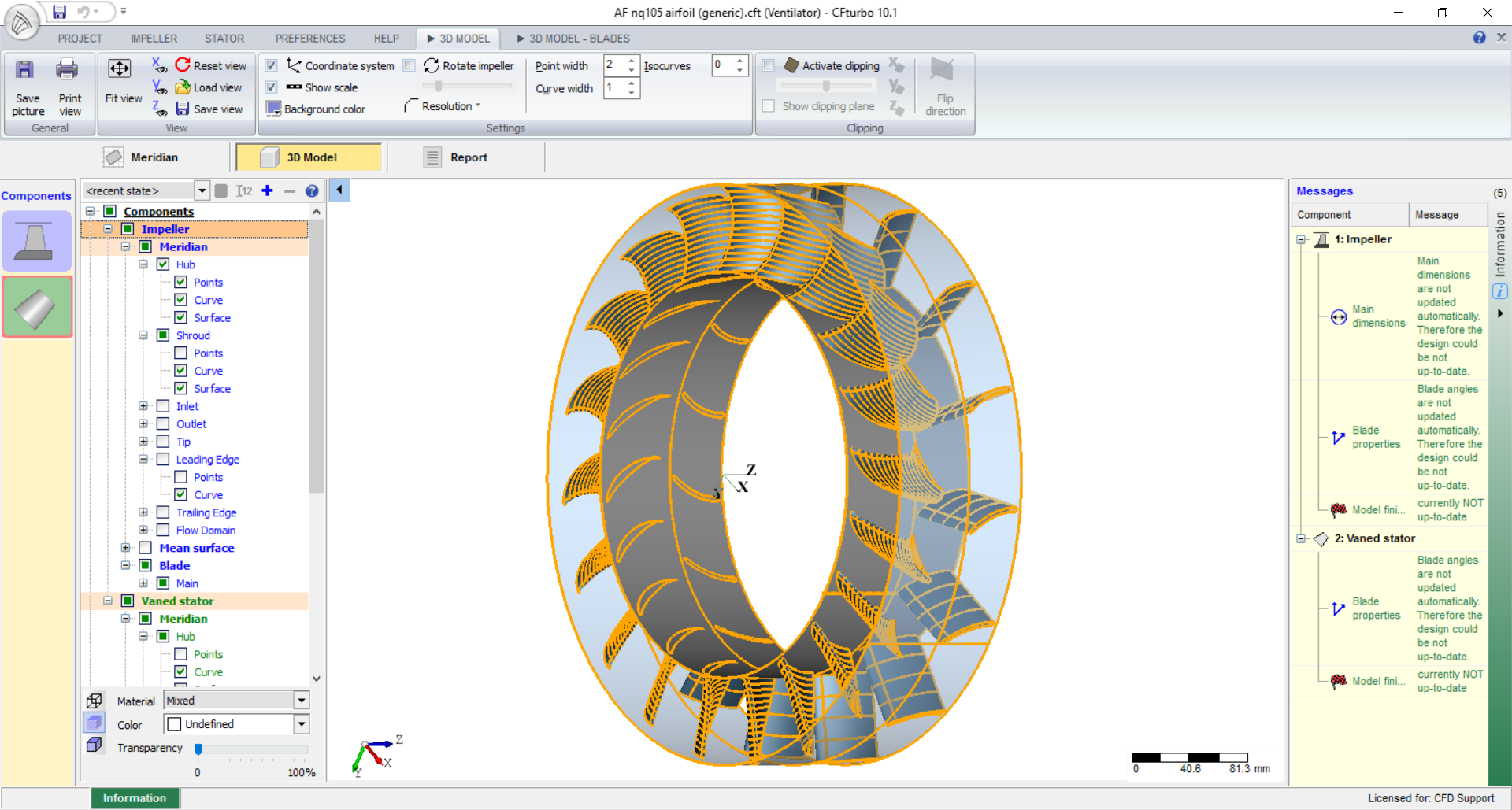

The axial fan is simulated using FLUENT software to prove an increase in airflow rate after using the guide vane. Considering the final results, it can be observed that the airflow is. An optimization method based on the gradient method to design the axial flow fan with efficiency and pressure selected as target objectives. They adopted 13.